30 years of experience

In providing professional engineering services and manufacturer of construction equipment

Reliable equipment

Reliable components

that ensure high efficiently

Unique engineering

Innovative developments

and engineering division qualification

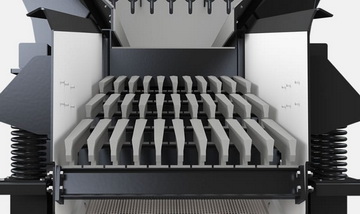

ABOUT FEEDERS

MEKA feeders belong to the category of additional equipment for crushing equipment. Their main purpose is the uniform and continuous supply of various materials immediately after their extraction for further screening or secondary crushing.

Main types of MEKA feeders

All MEKA vibrating feeders can be divided into three main categories:

- Standard models.

- Models with optional accessories.

- Models with auxiliary reservoirs

Feeders from the first group are used for uniform and stable feeding of various materials, from fine gravel to large rocks. The versatile design allows MEKA vibratory feeders to be used as a supplement to crushers or sites.

The models of the second category are equipped with a grid screen, which enables quick and efficient sorting of materials with coarse and medium fractions.

Models with auxiliary hoppers are used for continuous supply of crushed stone, gravel and stones to secondary crushing equipment. They are installed directly under the hoppers, which enables a quick and uniform output of raw materials from the warehouse.

Regardless of the type or model, MEKA feeders are equipped with the most efficient vibrators, have good abrasion resistance and are intended for long-term operation in demanding conditions. Any model has the ability to adjust the degree of vibration, which allows stable operation of the equipment even under maximum load. To reduce internal stress, all drive elements are thermally treated, which increases the life of the device. A large assortment of the assortment allows you to choose the right solution for working with different materials, depending on the performance of the feeder and its filling volume.

Due to the delivery directly from the factory and the absence of intermediaries, the price of our production is the most balanced in the market.